Auto body shops need to research and select specialty collision hardware tailored to specific vehicle models for accurate fitting, structural integrity, and aesthetic repair. Adhering to manufacturer guidelines is crucial for effective use, safety, and preventing further damage during dent repair processes.

“Uncovering Common Pitfalls in Specialty Collision Hardware Usage

Specialty collision hardware promises enhanced vehicle protection, but many users fall into traps that undermine its effectiveness. This article sheds light on three prevalent mistakes: choosing incompatible components, overlooking installation guidelines, and ignoring safety warnings. By understanding these errors, auto enthusiasts can ensure optimal use of specialty collision hardware, enhancing both vehicle security and peace of mind.”

- Misunderstanding Compatibility: Choosing the Wrong Components

- Inadequate Installation: Neglecting Step-by-Step Guidelines

- Overlooking Safety: Ignoring Manufacturer Warnings and Standards

Misunderstanding Compatibility: Choosing the Wrong Components

Many auto body shop owners and mechanics make the mistake of assuming that all specialty collision hardware is universally compatible with any car bodywork. This misunderstanding often stems from a lack of thorough research or experience with specific vehicle models. Each car model has unique design features, especially when it comes to the underbody and frame. What works seamlessly in one auto body shop’s collision repair process might not fit properly in another’s, leading to costly delays and subpar results.

When selecting specialty collision hardware, it’s crucial to consider the make and model of the vehicle. Different cars have distinct body panels, frames, and mounting points, requiring precise matching components. Using the wrong hardware can result in misaligned panels, weak structural integrity, and an unsightly finish. Therefore, auto body shops should invest time in understanding their vehicles’ specifics and choosing hardware designed to fit their car collision repair needs accurately.

Inadequate Installation: Neglecting Step-by-Step Guidelines

One of the most common mistakes when using specialty collision hardware is neglecting the step-by-step guidelines provided by the manufacturer. Many professional installers rush through the process, assuming their experience will ensure a seamless fit and proper alignment. However, each piece of specialty collision hardware is designed with specific requirements to ensure optimal performance during the repair or restoration process, such as car dent repair. Following these instructions is crucial for maintaining the integrity of both the hardware and the vehicle’s structure, especially in delicate areas like body shop services.

Ignoring the guidelines can lead to improper installation, which may compromise the overall quality of the repair work. The wrong mounting angles, inadequate tightening torques, or failure to account for clearance issues can result in hardware that doesn’t function as intended or even causes further damage to the vehicle. Understanding and adhering to the manufacturer’s recommendations is key to avoiding these pitfalls, ensuring the longevity and effectiveness of specialty collision hardware in body shop services and car dent repair processes.

Overlooking Safety: Ignoring Manufacturer Warnings and Standards

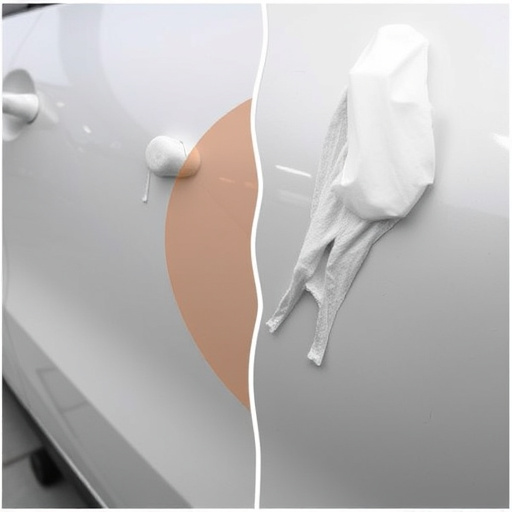

Using specialty collision hardware, designed for tasks like paintless dent repair and car dent repair, is a specialized skill that demands attention to detail and adherence to safety protocols. One of the most common mistakes made by enthusiasts and even some professional automotive repair shops is overlooking these critical safety measures. Manufacturer warnings and industry standards exist for good reasons—to protect both the user and the finished product.

Ignoring these guidelines can lead to not only compromised results but also potential hazards. Specialty hardware often requires specific techniques, tools, and environmental conditions to ensure a successful and safe outcome. For instance, using the wrong type of tool or failing to follow temperature recommendations during the healing process can cause damage to the vehicle’s finish or even result in accidents. Always prioritize safety by thoroughly reading and understanding manufacturer instructions before attempting any automotive repair, especially when employing specialized equipment.

When utilizing specialty collision hardware, avoiding common pitfalls is essential for successful installations. Misunderstanding compatibility, neglecting proper installation procedures, and overlooking safety guidelines can lead to subpar results and potential hazards. Always refer to manufacturer instructions and adhere to industry standards to ensure the best outcomes and protect against accidents. Understanding these mistakes and learning from them will help professionals navigate the complexities of specialty collision hardware with confidence.